Sensored motor solder tab vertical extensions make it easier to connect, route, and maintain both power and sensor lines on brushless motors without damaging joints or creating wiring stress. Many builders use them to improve access, reliability, and thermal performance, especially in tight spaces where flat tabs limit movement. When used correctly, these extensions create a cleaner and more dependable link between the motor and the controller, which is essential in high vibration or high current systems.

Understanding the Role of Vertical Extensions

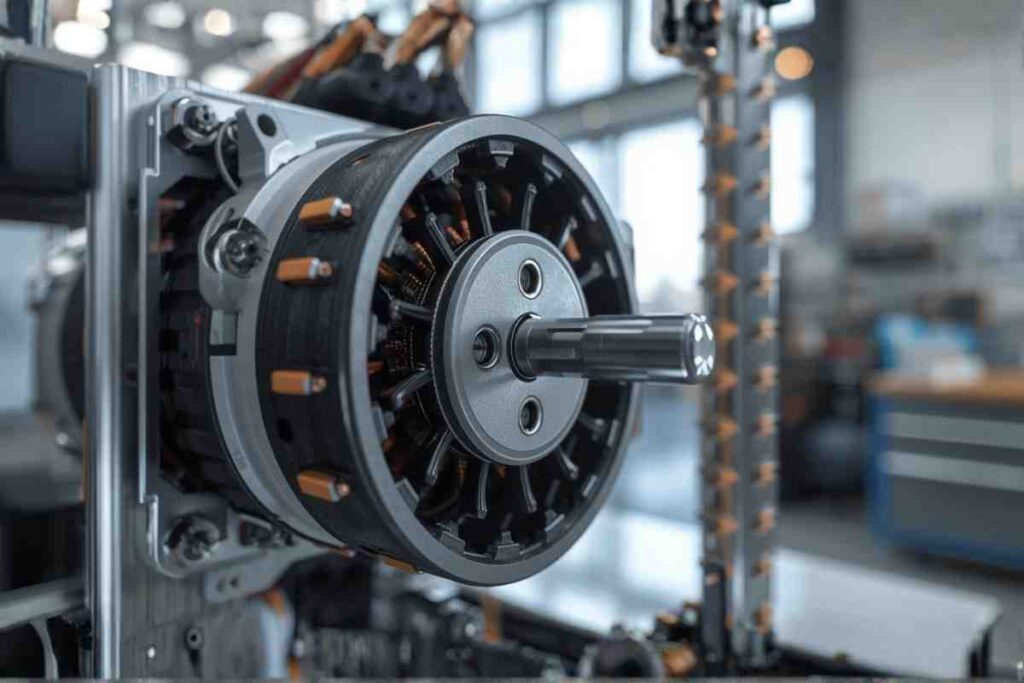

Sensored motors rely on two sets of connections. One carries the high current that powers the motor. The other carries low-level signals, such as Hall sensor data, back to the controller. When both sit close to the motor body, space becomes tight and soldering becomes difficult.

Vertical extensions lift these connection points upward. This helps with wire routing, reduces the chance of accidental bending, and keeps sensitive sensor wiring away from high-current paths. In projects with limited space, this small change can significantly improve performance and ease of assembly.

Accessibility and Wiring Comfort

One of the biggest advantages of using vertical extensions is how they simplify soldering and wire routing. Flat tabs can force your hands into awkward positions, especially inside dense installations like robotics housings, compact drone frames, or RC car chassis. When tabs sit upright, a soldering iron can reach them cleanly, and wires can be guided toward the controller without sharp bends.

In real projects, even a few millimeters of improved clearance can help prevent accidental heat exposure to nearby components or repeated strain on fragile sensor wires. This reduces the need for constant rework and supports long-term stability.

Reducing Mechanical Stress at the Joint

Solder joints on motors constantly deal with vibration, torque, and acceleration forces. When wires pull sideways on a flat tab, stress transfers directly into the solder. Over time, this can lead to cracks or complete joint failure.

Vertical extensions act as a buffer between the motor and the wiring harness. Because they stand upright, wires apply less twisting force on the joint. When the motor moves, the wire moves with a softer arc rather than a harsh bend. This is why builders who run vehicles on rough surfaces often rely on these extensions to prevent fatigue over long use.

A simple situation explains this well. In a small ground robot, the motor sits close to the wheel. Each bump shakes the motor, and without extensions, the wires flex sharply at the solder point. Adding vertical extensions delays that bending action further along the wire, keeping the critical joint stronger and more reliable.

Improving Thermal Behavior in High-Current Paths

Current flowing through a joint generates heat. This effect increases if resistance rises due to oxidation, thin solder coverage, or undersized metal. Vertical extensions typically use thicker metal or larger surface areas compared to small tabs pressed against a motor housing.

Additional surface area encourages better heat spreading. For systems that run continuously or under heavy load, even small improvements in heat stability help. They keep solder joints strong and prevent softened or fatigued solder from breaking under movement.

When used together with proper wire gauge and clean soldering technique, vertical extensions contribute to a more efficient electrical path.

Maintaining Clean Sensor Signals

Sensored motors rely on Hall sensors or encoders to report motor position. These signals are low current, and any noise can distort the data. When power wires sit too close to sensor lines, electromagnetic interference becomes a risk.

Vertical extensions help create physical separation. By lifting connections upward, you gain the freedom to route power leads and sensor wires in cleaner, independent paths. This space reduces EMI exposure and keeps signals more stable.

This matters in precision applications. For example, in a robotic arm using a sensored BLDC motor for positioning, any signal dropout might cause small but noticeable jitter. Clean routing supported by vertical extensions helps maintain smooth motion and accurate feedback.

Choosing Quality Materials for Strong Performance

A reliable extension starts with the right material. Copper or copper alloys are most common because they carry current efficiently. A plated surface, such as tin or silver, helps the solder flow better and protects against oxidation.

Thickness matters as well. The cross-section must handle peak current without unnecessary resistance. If you regularly push your motors to high load scenarios, choosing a thicker extension prevents heat buildup and prolongs the life of every connection.

When evaluating extensions, simple details like consistency in thickness, smooth edges, and even plating make a noticeable difference during soldering.

Insulation and Safe Separation

Sensored motors require a careful balance between high-current power links and delicate sensor wires. Vertical extensions improve physical alignment, but insulation remains vital.

Using heat-resistant plastics, heat-shrink tubing, or small insulating barriers can prevent accidental shorts. Extensions that include built-in insulating spacers make installation even easier. The goal is to ensure that each path carries only the signals intended for it, without cross-contact or leakage.

In environments with heavy electrical noise, pairing sensor wires into twisted pairs or adding simple shielding helps maintain clean data transmission.

Designing for Compact Projects

Many projects limit vertical space. In that case, a low-profile extension with just enough lift can still provide benefits without blocking other components. Some builders use small PCB-style adapters that lift the solder pads only slightly while offering clean routing and labeled connections.

A compact design is especially useful when the motor sits in a tight space, such as inside a drone motor mount or a compact gearbox. Even a small lift can make wire organization easier and reduce the load on the solder joints.

Mechanical Stability and Strain Relief

Good mechanical design treats wires as flexible, moving elements. Solder joints are not meant to bend repeatedly. Strain relief keeps forces away from the joint and distributes movement across the wire length.

Extensions benefit from simple support structures like fillets, reinforced bases, or flexible loops of wire. Many builders use a small cable clamp or zip tie close to the extension post. This prevents the wire from pulling directly on the solder when the system vibrates or rotates.

Over time, this extra support plays a major role in maintaining reliability, especially in high-vibration environments.

Ensuring Proper Fitment With the Motor

Every motor model has its own spacing and tab layout. Extensions must align perfectly with the motor’s original tabs. A slight misalignment can stress the joint, create air gaps, or weaken conductivity.

Some manufacturers create model-specific extensions that match motor geometry exactly. These are easiest to install because they guarantee spacing and orientation. If you work with custom motors, measuring tab dimensions and spacing before choosing or designing the extension helps ensure a clean and safe fit.

Practical Installation Steps

A careful installation protects both the motor and the extension.

Preparing the Tabs

Start by cleaning the motor tabs with alcohol or a light abrasive. Removing oxidation ensures a cleaner bond. Do the same for the extension surfaces.

Aligning the Parts

Hold the extension firmly against the motor tabs. Using a small fixture or clamp helps keep everything aligned until soldering is complete.

Applying Flux and Heat

A small amount of flux makes solder flow smoothly. Use a controlled soldering station so the motor and magnets do not overheat. Power connections should be soldered first because they require more heat and form the main structural support.

Securing Sensor Lines

Sensor wires need only a small amount of heat. Moving quickly and carefully protects the internal sensors. Avoid holding the iron in one place for too long.

Inspecting Your Work

Check that each joint has smooth, complete coverage with no gaps or unintended bridges. A quick continuity check confirms solid electrical connections.

Preparing for Use

Before installing the motor into your project, spin it gently and verify that the controller reads sensor data correctly. Watching for abnormal noise, heating, or unstable readings helps prevent problems later.

Ongoing Maintenance for Long-Term Reliability

Connections naturally age, especially in high-vibration systems or environments exposed to dust or moisture. A quick inspection every few months helps catch issues early.

If you notice higher resistance than usual, it may indicate oxidation or cracked solder. Reflowing the joint or cleaning the surface usually resolves the problem. For sensor noise or unexpected dropouts, reviewing the routing and checking for damaged insulation often brings the system back to normal.

Keeping logs of how often issues appear can help identify patterns and prevent future downtime.

Typical Applications Where Extensions Shine

Vertical extensions are especially helpful in systems where access is limited or reliability is critical. RC vehicles, drones, industrial motors, and small robotic actuators all benefit from improved wiring clearance and easier maintenance.

In research and development projects where motors are swapped frequently, these extensions save time and reduce wear. They also make testing setups cleaner and more predictable because the wiring behaves consistently from one configuration to another.

Final Thoughts

Sensored motor solder tab vertical extensions offer a simple way to improve wiring access, reduce stress on solder joints, and maintain clean sensor signals. They make motors easier to install, maintain, and trust in demanding environments. When designed and installed with care, these extensions help create a stronger electrical path and a more dependable connection between your motor and controller. For anyone working with compact layouts, heavy loads, or frequent maintenance cycles, using a quality extension can make a noticeable difference.

FAQs

Do I need special tools to install sensored motor solder tab vertical extensions?

You only need a good soldering station, flux, and basic cleaning tools. A small clamp or fixture helps keep everything aligned while soldering.

How do I know if my motor actually needs vertical extensions?

If you struggle with tight wiring spaces, repeated joint failures, or messy routing near the tabs, extensions can make your setup cleaner and more reliable.

Can sensored motor solder tab vertical extensions affect motor performance?

They do not change motor performance directly. They improve wiring access, reduce stress on joints, and help keep sensor signals clean.

What is the safest way to route sensor wires after installing extensions?

Keep sensor wires away from power leads, give them gentle bends, and use basic insulation. This reduces noise and keeps the signals stable.

How often should I check the solder joints after installing these extensions?

If your setup vibrates a lot, check every one to three months. For lighter use, a quick inspection every few months is usually enough.